Research and Development

Innovation – Made in Germany

SAFETY THROUGH MODERNIZATION

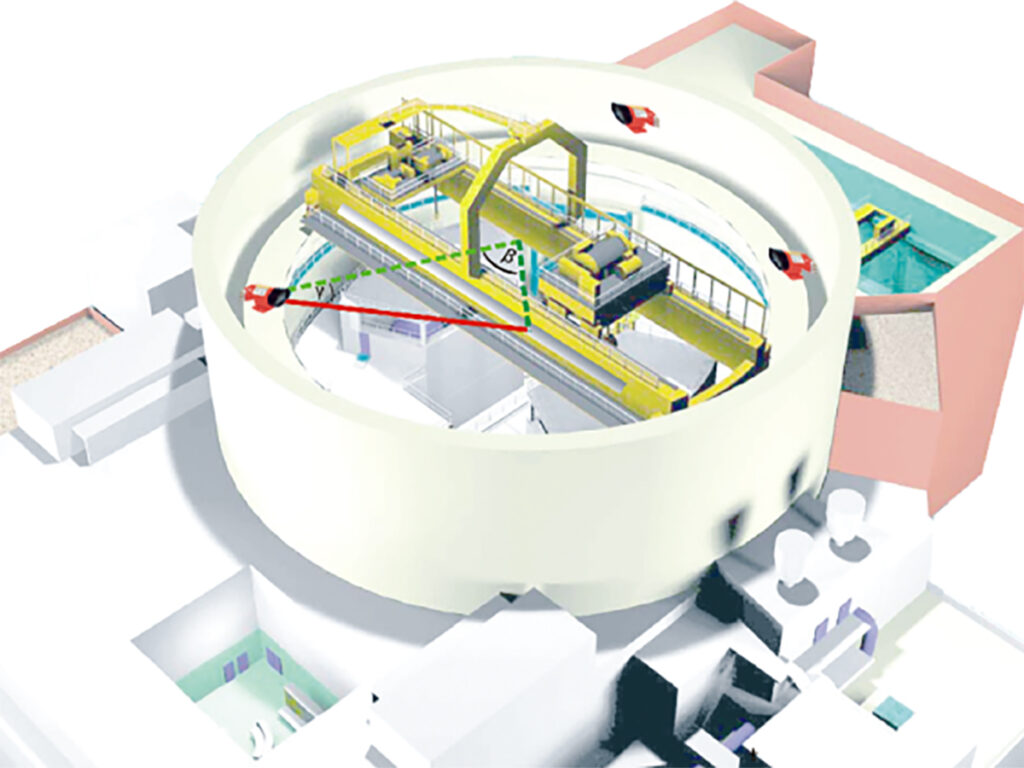

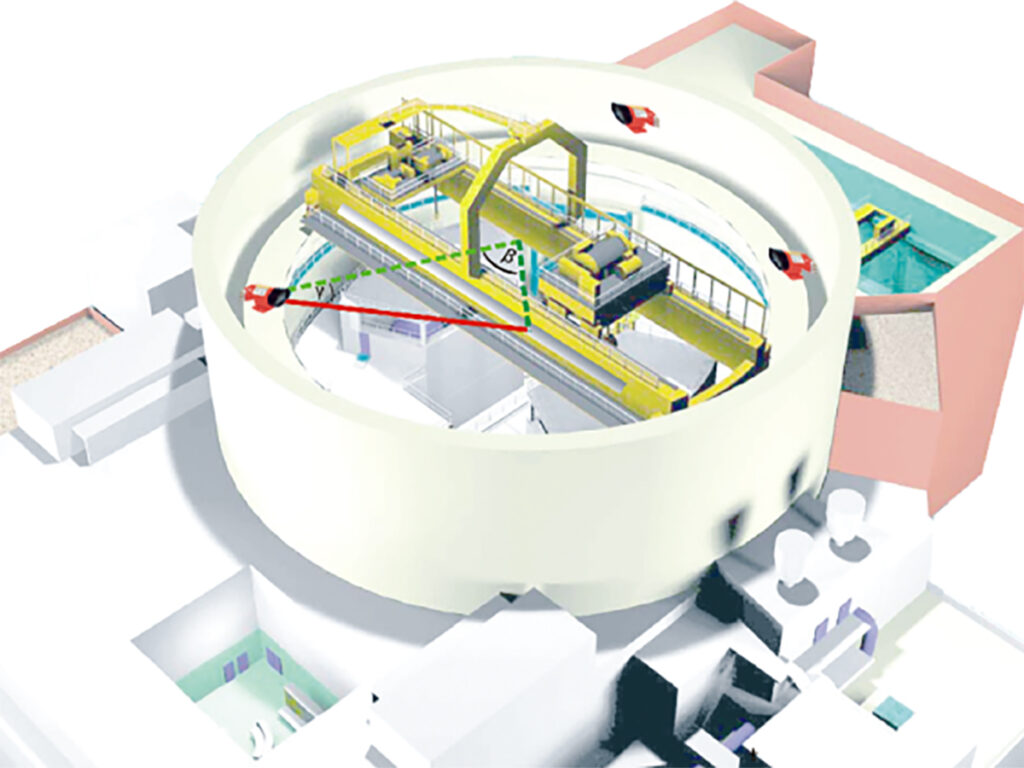

The safe and efficient modernization of nuclear power plants is one of the central challenges of our time – especially for Russian-designed reactors of the WWER1000 type, which are operated in many Eastern European countries. Our research and development department is dedicated to optimizing circular cranes that play a key role in these plants. Design-related weaknesses often lead to increased wear and tear and pose risks to reactor safety. Through innovative technical solutions and close cooperation with the responsible nuclear energy authorities, we are working to avoid downtimes, increase safety standards and sustainably improve operational efficiency.

The geometric parameters of the crane travel specified in the crane design change significantly during crane operation under the influence of mechanical and climatic factors. Extreme deviations of the geometric path parameters from the design lead to an increase in the load on the chassis and the metal structure of the crane. Increased loads lead to premature failure of expensive and difficult-to-replace crane components and to unplanned downtimes in the crane cycle.

More Safety

Cost Savings

Avoidance of Downtimes

With the Solutions We Offer, You Achieve:

SKET – DEVELOPMENTS

We offer you a turnkey modernization of control systems for overhead cranes. Our service package consists of the following three products:

Non-contact Laser System for Determining the Spatial Coordinates of the Load Suspensions of the Polar Crane

Adaptive Synchronization System of the Bridge Sides of the Polar Crane

Automated Control System for the Geometric Parameters of the Crane Runway of the Polar Crane

Precision meets safety:

The Non-Contact Laser System for Polar Cranes

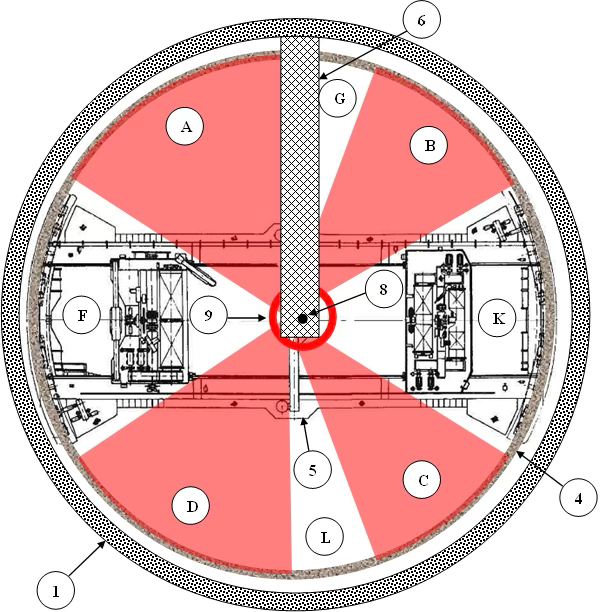

Our innovative laser system was specially developed for use in safety-critical industrial environments such as reactor buildings. It enables the exact, non-contact acquisition of the spatial coordinates of load suspensions on polar cranes – reliable, low-maintenance and in real time.

Technology that convinces

The system uses six high-precision laser rangefinders, which are mounted on the crane at an angle of 60°. The sensors are evenly aligned at an angle γ and record the distance to reflective plates on the bridge girder. Depending on the position of the crane bridge, the measurement data is processed in pairs (sensors 1 & 4, 2 & 5, 3 & 6).

A specially developed algorithm calculates the angle of rotation of the crane bridge based on geometric parameters such as running radius, crane dimensions and sensor angle. The offset of the bridge is also taken into account – for precise angle determination according to the law of cosines.

Based on this data, the Cartesian coordinates of the trolleys (320 t, 160 t, 2×70 t) and the load suspensions are calculated. The positions are determined in real time and can be directly integrated into the control systems.

Your Advantages at a Glance

Non-contact & Low-Maintenance

No mechanical wear parts – ideal for continuous operation in safety-relevant areas

Highest Precision

Exact angle and position calculation through intelligent sensor networking and mathematical modeling

Real-time Data for Maximum Control

Immediate availability of coordinates for safe and efficient crane movements

Scalable and Adaptable

Suitable for various crane loads and configurations

Precision in motion – for maximum safety in the nuclear power plant

Adaptive Synchronization System FOR Polar Cranes

In nuclear facilities, every movement counts. The adaptive synchronization system for polar cranes developed by SKET-Spezialkran offers highly precise control of the bridge sides – even under extreme mechanical and climatic conditions.

Why this system?

Crane runways in nuclear power plants are exposed to mechanical and climatic influences that can lead to deformations and deviations. Our system ensures that both sides of the crane bridge operate synchronously and reliably – regardless of track deformations.

The core functions

Synchronized movement: The constant linear speed of both bridge sides ensures that the same distance is always covered at identical time intervals – regardless of deformations of the crane runway.

Geodetic monitoring: Regular surveys of the crane runway record height deviations (dHc) between diametrically opposite points. This data is graphically and tabularly processed and integrated into the SCADA system WinCC.

Automated correction: Specially developed software processes the survey data and generates precise correction recipes for speed and acceleration. These are transferred directly to the automation system Simatic S7-400.

Intelligent control: The correction values are fed into the SIMOREG encoders in real time, which achieves a true synchronization of the bridge sides – regardless of the shape or deformation of the crane runway.

For whom?

This system is aimed at operators of nuclear power plants who place the highest demands on safety, precision and reliability. It is ideal for modernization projects as well as for the new construction of crane systems in sensitive areas.

Your Advantages at a Glance

Maximum Operational Safety through Continuous Adaptation to Real Track Conditions

Minimization of Wear and Structural Loads

Seamless Integration into Existing Automation Systems

Highest accuracy – directly in the containment

Automated Control System for Crane Rail Rings

In nuclear facilities, the exact geometry of the crane infrastructure is crucial for safe and trouble-free operation. The system for automatic control of the geometry of crane rail rings developed by Georg Krüger was specially developed for use in hermetic containments of WWER/PWR reactors and offers a high-precision, automated solution for monitoring and adjusting the monorail of circular bridge cranes – directly in the containment and without manual measurements, without scaffolding, without interruption of operation.

Why is this important?

Mechanical and climatic influences lead to geometric deviations in the crane rail ring over time. These can lead to uneven crane movement, increased wear and, in the worst case, to safety-critical loads. Conventional manual measurement methods are complex, prone to errors and associated with long downtimes.

The solution:

An Intelligent Information System

Our system enables fully automatic, geodetic measurement of the monorail – without reflectors, without scaffolding, without interruption of technological processes.

Technical highlights:

Volumetric laser scanning: High-precision distance measurement without reflectors, controlled by electric precision drives.

Automated data acquisition and processing: Transmission of the measurement data via Profibus to Simatic S7-400H, with graphical and tabular evaluation.

Flexible control: Operation via the crane control panel or a mobile remote control panel with display – intuitive and efficient.

Optimal placement of the sensors: Installation in protected locations within the containment to minimize external influences.

Advantages for the Operator

Reduced Downtimes

Measurement and adjustment take place parallel to maintenance – without restricting technological processes.

Increased Operational Safety

Early detection and correction of geometric deviations protects against incorrect loads and wear.

Seamless Integration

Compatible with existing automation and control systems.

Maintenance Optimization

Eliminating manual measurements and complex scaffolding saves time and resources.

VIDEO

Functionality of the Control System

We provide comprehensive solutions and support to help you reach new heights.